Spencer Walker-Fooks

Systems Engineering, Product Software Development and Hardware Design

Robotic Vacuum Cleaners

Designed Sensors, Software and Test Rigs for Robotic Vacuum Cleaners

E-Ink Personal Tracker Display

Full Product Design and Development and Testing, Systems Engineering

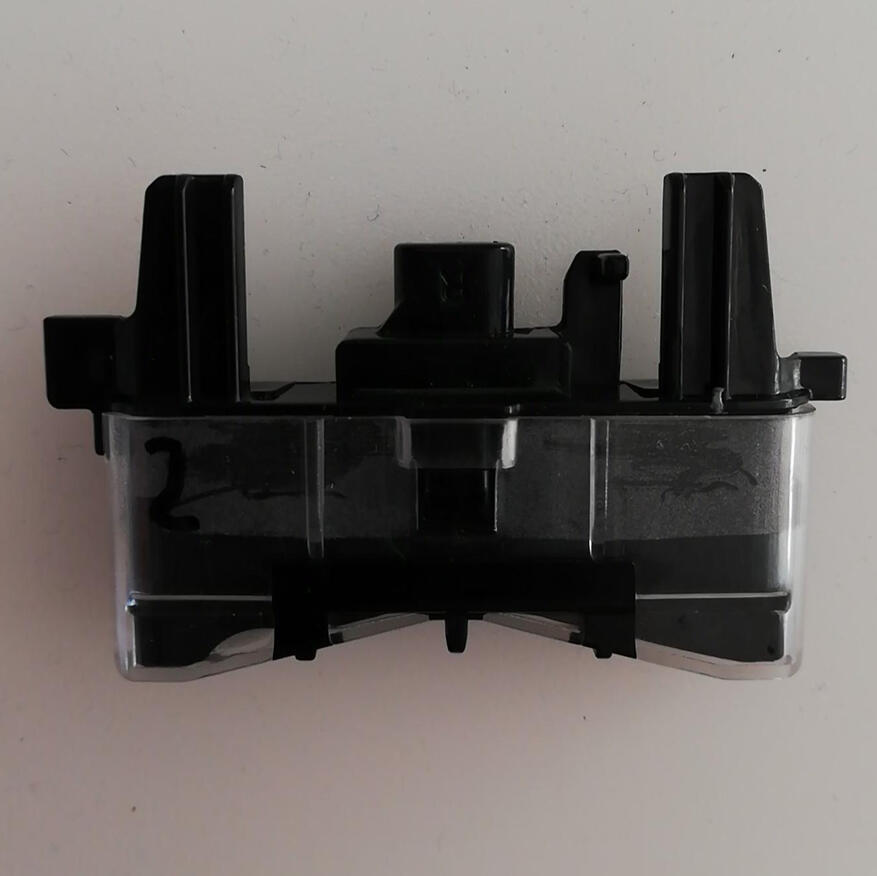

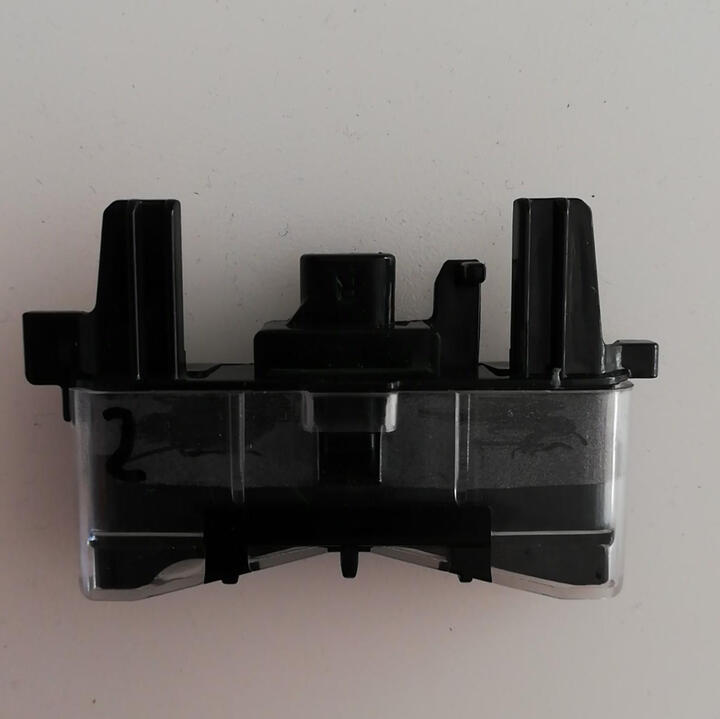

Floor Surface Sensor

Developed a Floor Surface Sensor for Robotic Vacuum Cleaners to differentiate between Floor Types

I worked on robot vacuum cleaners for 4 years. This entailed work on sensors development, software development, the designing and building of proof of concepts and test rigs.As a Senior Mechatronics Engineer, I played a pivotal roles in the Advanced Development team, leading prototype technology development for new product lines. I coordinated with global teams, integrating mechanical, electrical, and software engineering disciplines. This included the development of several unique sensors on the robots, taking them from initial proof of concept to mass production.I tackled challenges in interdisciplinary coordination and technology integration, ensuring our innovative solutions aligned with both technical and commercial objectives. This was further accentuated by my later work as a Systems Engineer which is focused on assessing the entire system as a whole and evaluating trade-offs between different options.

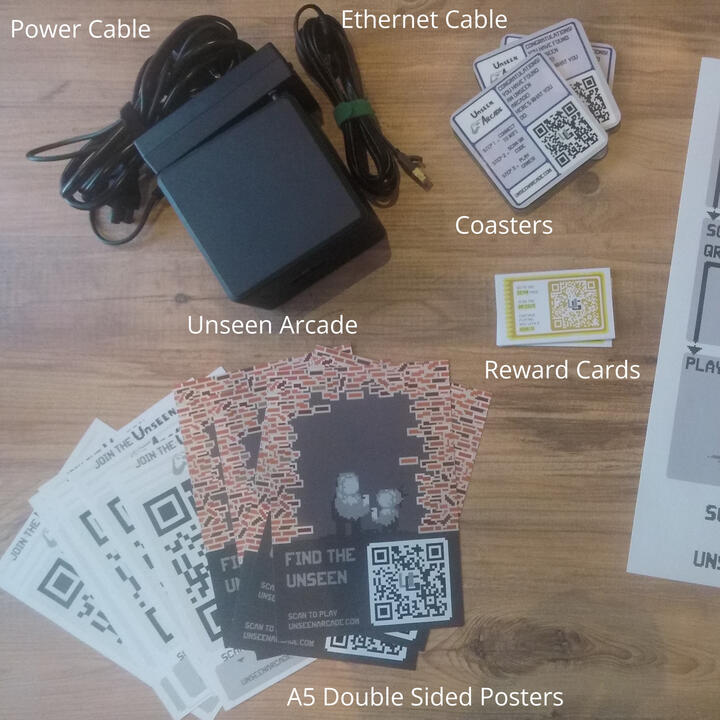

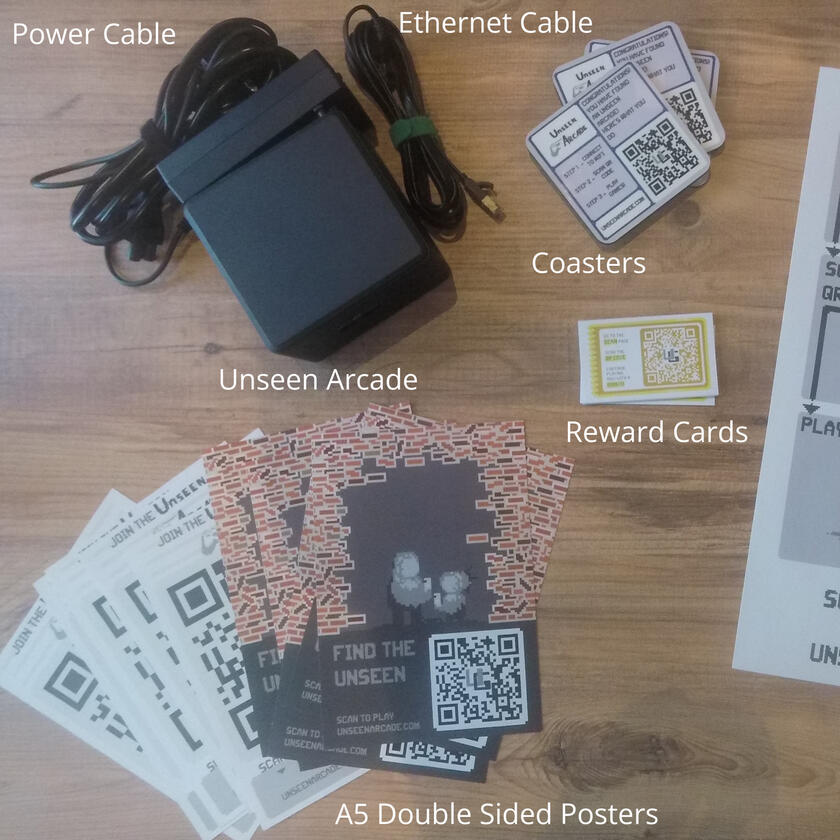

Unseen Games was a company I started focused on a social gaming console designed specifically for pubs.For this I designed the system architecture, including Jenkins CI/CD pipeline, Redis and SQL databases, Auth0 authentication and Game design (single and multi-player). Furthermore I lead our team of 4 to develop the games, do player testing, integrate the feedback and iterate on the user experience.The implementation of the product required taking into account the user experience, the value proposition for pub owners and the potential extra workload on bartenders/waitstaff at the pubs.

BioCarbon Engineering, (now renamed to Dendra Systems) is the original drone reforestation company. Where I worked as the Product Lead and provided the mechanical engineering design for the deep planting mechanism, and broad spreading mechanism.These both entailed system engineering to integrate the payload functionality with the drone's capabilities and needs.The deep planting system required a great deal of CAD design to ensure that seedpods (containing seeds) can propagate through the deep planting mechanism.I designed the entire broad spreading system from scratch to ensure that we were able to deliver sufficient seeds of given types to achieve the level of growth desired.

An E-Ink tracker for personal tracking information such as investments or podcast download numbers. This incorporates software, electrical design, and basic CAD design.I designed the full software architecture for the system. This includes api requests to several platforms, image manipulation, data analysis and linux systemd management.

For this project I provided a sensor for determining the different floor types that a robotic vacuum would operate on. For this I provided the physics analysis, resultant mechanical design, electrical design, and software development. As I provided the product well under the specified cost, whilst meeting the detection requirements this system was taken from the Proof of Concept all the way to mass production in the robot vacuum cleaners.At mass production I provided test rig designs and worked with the DFM team to ensure the sensor could be produced at sufficient scale for our robots. When issues arose in the factory requiring changes to the sensors, I played a pivotal role in the root cause analysis and providing the solution both in the factory and for already delivered robots.

Contact